The Vital Duty of Galvo Scanners in Accuracy Laser Positioning and Control

Galvo scanners, essential to the accuracy and control of laser positioning, use high-speed turning mirrors to accomplish unrivaled precision in directing laser beams. What makes these tools essential in settings demanding thorough laser operations?

Understanding Galvo Scanner Innovation

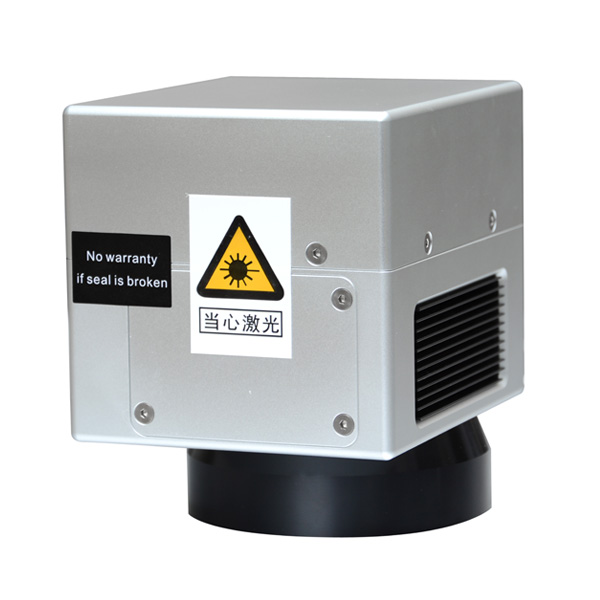

In the realm of laser positioning, understanding Galvo scanner modern technology is extremely important for achieving precision and performance. Galvo scanners, short for galvanometer scanners, use mirrors installed on galvanometers to route laser light beams with high precision and rate. These mirrors can quick, exact angular activities, enabling the laser beam to be directed to specific collaborates on a target surface area.

The operational principle of a Galvo scanner focuses on the galvanometer mechanism. A galvanometer transforms electric current right into mechanical motion, causing the mirror to pivot. By managing the electric current, the mirror's angle is accurately manipulated, enabling for specific laser positioning (galvo scanner). This is critical in applications such as laser engraving, clinical imaging, and optical interaction, where precision is important.

High-resolution encoders are usually incorporated right into Galvo scanners to supply real-time responses on the mirror's placement, ensuring very little deviation from the intended path. This responses loop boosts the scanner's precision and repeatability, making it an essential device in industries needing meticulous laser support. Comprehending the intricacies of Galvo scanner modern technology is hence vital for leveraging its full potential in innovative laser applications.

Mechanisms of Laser Positioning

Reliable laser placing counts on numerous advanced devices to achieve high precision and accuracy. At the heart of these systems are galvanometer (galvo) scanners, which utilize revolving mirrors to direct the laser light beam with remarkable rate and control. The core concept includes converting electric signals into exact angular movements through the galvo motor, which after that readjusts the mirror's orientation to guide the laser beam of light to the desired area.

An additional critical part is the control system, which incorporates comments loops to continually check and fix the laser's setting. This makes sure marginal discrepancy from the target collaborates, enhancing the total accuracy. The usage of sophisticated servo controllers allows for real-time adjustments, making up for any kind of disparities that may arise throughout operation.

These mechanisms jointly make it possible for specific and trusted laser positioning, critical for applications requiring stringent precision.

Advantages of Making Use Of Galvo Scanners

Galvo scanners use many benefits that make them essential in precision laser applications. The high-resolution responses systems incorporated right into galvo scanners ensure minute adjustments, thus enhancing accuracy and repeatability in laser positioning.

Furthermore, galvo scanners show exceptional adaptability. They can be configured to carry out intricate scanning patterns and accommodate various beam of light sizes and shapes. This flexibility is essential for tasks that demand detailed laser paths, such as inscribing thorough designs or carrying dig this out fine operations.

Dependability is another essential advantage. Galvo scanners have a robust layout with minimal relocating parts, decreasing the chance of mechanical failure. This leads to longer functional lifespans and lower upkeep expenses, making sure consistent performance over extended periods.

Furthermore, the compact form element of galvo scanners allows for very easy assimilation into diverse systems. Their small size does not endanger their efficiency, making them appropriate for applications with spatial restraints.

Applications in Numerous Industries

Laser placing systems using galvo scanners have actually changed numerous industries by enhancing performance and accuracy. In the production field, these systems are indispensable to laser cutting and engraving processes, supplying exceptional precision and speed. Automotive and aerospace sectors gain from the specific welding and boring capacities of these systems, making certain elements satisfy stringent quality requirements.

In the medical area, galvo scanners are essential in laser surgery and eye therapies, where accuracy is important for individual security and effective end results. Dermatology and aesthetic procedures likewise rely upon these systems resource for jobs like tattoo removal and skin resurfacing. The electronics market utilizes galvo scanners for PCB (Printed Circuit Board) construction, allowing the production of elaborate circuit patterns with high repeatability.

In addition, in the area of scientific study, galvo scanners are critical in advanced microscopy strategies, such as two-photon and confocal microscopy, permitting researchers to record high-resolution images of organic specimens. The art and amusement markets likewise make use of these systems in laser light programs and holography, creating dynamic aesthetic experiences. On the whole, the flexibility and accuracy of galvo scanners drive technology and operational excellence across a multitude of markets.

Future Innovations and Fads

As technical innovations proceed to accelerate, the future of galvo scanners in laser positioning systems assures groundbreaking developments and arising fads. One substantial pattern is the assimilation of expert system (AI) and equipment understanding (ML) formulas to boost the accuracy and adaptability of galvo scanners. These intelligent systems can predict and remedy deviations in real-time, bring about greater accuracy and performance in laser applications.

An additional arising pattern involves the advancement of ultra-fast galvo scanners with the ability of managing higher laser power and rate without endangering on precision. This innovation is especially vital for markets such as semiconductor production and medical gadget manufacture, where even minute mistakes can lead to substantial losses.

Moreover, the miniaturization of galvo scanner components is anticipated to open up new applications in wearable and mobile gadgets (galvo scanner). Breakthroughs in micro-electromechanical systems (MEMS) innovation are leading the way for even more small, yet extremely reliable, galvo scanners

Lastly, Homepage raised concentrate on sustainability and energy performance will drive the development of green galvo scanner systems. By integrating energy-efficient elements and maximizing operational methods, future galvo scanners will certainly not just boost performance yet likewise contribute to an extra lasting technical environment.

Conclusion

Galvo scanners are essential in precision laser positioning and control due to their capability to transform electrical signals right into accurate angular motions. These characteristics make galvo scanners crucial in markets calling for careful laser procedures, such as laser engraving and medical treatments.

Galvo scanners, indispensable to the precision and control of laser positioning, use high-speed revolving mirrors to accomplish unmatched precision in guiding laser light beams. Galvo scanners, brief for galvanometer scanners, make use of mirrors installed on galvanometers to direct laser light beams with high accuracy and rate. The high-resolution comments systems integrated into galvo scanners make sure minute modifications, hence boosting precision and repeatability in laser positioning.

Comments on “Just How a Galvo Scanner Boosts Laser Marking and Inscription”